This means maintaining the safety of our workforce, subcontractors, suppliers, members of the public and the environment always.

Ovenden Allworks has our own, dedicated in-house, Health and Safety Manager who is responsible for implementing our Health and Safety systems, ensuring our Health and policy is adhered to.

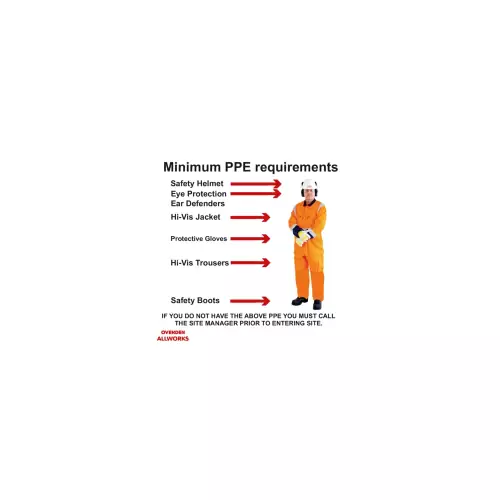

As a minimum, all employees must wear Personal Protective Equipment (PPE). We have provided all our workforce with full hi-visibility workwear, which consists of hi-visibility trousers and hi-visibility long sleeved polo shirts, plus all-in-one hard hats which include retractable safety glasses as well as ear defenders.

All tasks are undertaken by competent operatives who have completed the correct training. The training in monitored by a live ‘Training Matrix’, which is used to ensure the correct personnel are deployed to the projects that require specific capabilities.

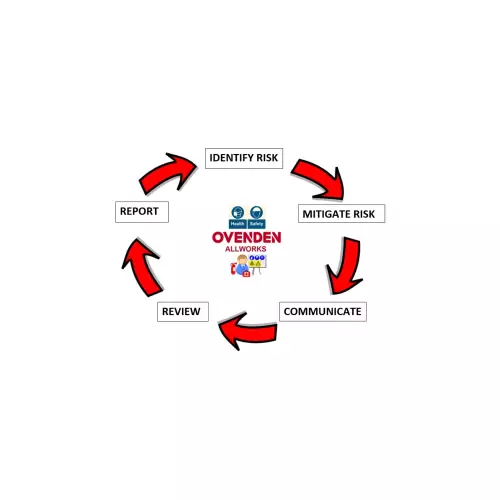

Once a project has been secured, we follow a 5-step procedure to ensure the works are undertaken in a safe and responsible manner.

Ovenden Allworks is a member of Constructionline and are Acclaim Health and Safety certified. We are members of the Civil Engineering Contractors Association. We are a Section 278 approved contractor for Kent County Council. We also have ISO 14001(Environmental certification), ISO 9001 (Quality Assurance).